|

VIBRO-

SEPERATOR

GENERAL :

The vibro seperator is system design for recycling

of various scraps and work as heart of the recycling

industries. The system consists of two different stages

in single operation. The system is having combination

of magnetic seperator and vibratory screening machine

in a single operation. Advantages of the vibro-seperator

recovery of valued material. The system is very efficient

and having low operational cost compare to the recovery

of valued material or metal

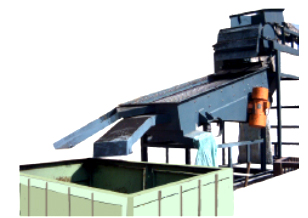

The system is available in two different design as

shown in pictures.

1. As shown in picture no.1 the crushed material

to be feed in the vibratory screen and will be screened

out , undersize material will be directly feed to

magnetic seperator , the magnetic seperator will separate

the magnetic material , thus we can achieve screening

and magnetic separation in single operation .

i.e In steel industries induction furnace slag having

some percentage of MS , the slag will be crushed and

charged to vibro seperator , the undersize is directly

fed to magnetic seperator and we get the recovery

of MS without slag impurities.

2. As shown in the picture no. 2 the crushed material

to be fed to magnetic seperator first and than it

go to vibratory screen.

i.e In rubber recycling industries rubber scrap will

be crushed and charged to magnetic seperator , it

separate the steel wires and the material directly

fed to screening machine and they get the screen rubber

material without iron imurietreis,

Features: Heavy Duty Construction, Low Maintenance,

Noiseless in operation, Available in Single, Double

& Triple Decks, and Dust Proof cover optionally

provided. Standard available sizes are of 1500 mm

(L)x 600 mm (W), 2000 mm (L)x 1000 mm (W), 2500 mm

(L)x 1200mm (W). Special customized sizes can be designed

as per requirments.

Applications: Vibro seperator are most useful in

industries like foundry / induction furnace slag ,

rubber recycling industries , Aluminum scrap recycling

industries , Iron powder manufacturing industries

, House west recycling industries, plastics west recycling

, and allied industries.

|